Location, Location, Location: How a Properly Located Chemical Manufacturer Can Lower Your Total Cost

- February 15, 2022

- Blog

In choosing a chemical manufacturer, there’s more than meets the eye when it comes to your total costs.

The one that’s cheapest upfront may prove to be quite expensive in the long run–or even the short run–if your supply of chemicals gets interrupted for any reason. And there are many reasons why it could.

So before you sign a contract, consider the effect location can have on the service you end up receiving and the mitigating factors you should explore first.

Impact of COVID-19 on Chemical Distribution

Supply chain issues related to COVID-19 and associated political and economic factors in recent years have highlighted the connection between raw materials’ geographic location, cost, and availability. By mid-2021, experts were already predicting shipping delays to last into 2022, but as the new year dawned, it quickly became clear that not only were problems lasting, they were worsening.

China, the world’s largest chemical manufacturer and exporter, has experienced severe labor shortages–particularly in factories and “blue-collar” jobs–that have combined with the country’s “dual-control” energy conservation policy to hamper chemical production in the country.

Unsurprisingly, chemical costs have ballooned during this time, too. For example, much has been publicized about agrochemicals’ historic price increases, with anhydrous ammonia at record highs and global potash rapidly approaching its 2008 peak.

A significant chunk of these price increases stems from the high cost of shipping, which has been fueled by a scarcity of containers, jammed ports, dock worker shortages, and more.

10 Ways Your Chemical Manufacturer’s Location Can Impact Your Bottom Line

#1 Customer Proximity

When you work with a contract manufacturer that can handle everything from manufacturing to packaging and shipping, you don’t necessarily need to be close by–the distance to the end customer may be more important.

The ability to reduce transportation time and therefore costs may be more valuable than your ability to oversee production, which can effectively be done remotely via GPS tracking and other real-time, web-accessible data.

It should be noted that customer proximity depends on the concentration of the market. In other words, you’ll only see cost savings if the manufacturer is closely located to a majority of your customers, not just a small percentage with the rest scattered.

#2 The Product Volume/Cost Mix

Another caveat to the ‘customer proximity’ question is that not every type of product will see good returns if produced far from the customer base.

For example, fertilizer and cement–two products that are low-cost but expensive to ship long distances due to their weight and bulk–would benefit your bottom line more by being manufactured close to their final destination.

But products such as pharmaceuticals or other high-dollar chemicals may not need to be manufactured close to the customers as shipping them will not make such a negative impact on their ROI.

#3 Free Trade Zones

Engaging a chemical manufacturer in a free trade zone–or foreign trade zone (FTZ) as they’re known in the U.S.–can lower your total costs by giving you access to benefits such as duty exemptions, deferrals, or reductions on raw materials, depending on the zone. The benefit of having Customs supervision may help lower your security and insurance costs, as well.

#4 Business Area

If you ever decide to expand your product lines beyond the capacity of your chosen manufacturer, having other manufacturers close by would enable you to stay efficient and keep costs down by contracting with them, as well. For example, it would be relatively easy to combine shipments, visit each with one trip, etc.

#5 Transportation Options

For bringing in raw materials, advancing chemicals to another stage of their production, moving finished products, and even dispatching personnel, convenient transportation is a must.

Having highway access for trucking is typically not an issue in the U.S., but bulk chemical shipping typically demands either ocean freighting or rail delivery, with air cargo the least popular option for its high costs.

A manufacturer that has on-site access to a rail line can be invaluable for large chemical shipments. Although trucks are more flexible and may be better for short distances, railroads are faster over long distances, can handle larger amounts at once, and are more fuel-efficient.

#6 Sustainability

Speaking of fuel efficiency, it’s becoming increasingly apparent that eco-friendliness can lead to lower costs and not just “soft” benefits.

Selecting a manufacturer that can cut down on shipping distance could save you extra money the shipper has to add to cover increased emissions taxes, such as those the State of California imposed in recent years. The National Highway Traffic Safety Administration (NHTSA) recently reopened the pathway for all U.S. states and localities to pass similar emission standards, which 23 states had sued the Trump administration to have reinstated.

#7 Risk Factors

Some locations are inherently riskier than others due to extreme weather events such as hurricanes and flooding (e.g. the Gulf Coast), landslides (California), extreme heat (Arizona), and more. These events can cause damaged products and delayed shipping times, especially if your chosen location does not have emergency power generation and other backup measures in place.

But weather is not the only risk element at play; there’s also the human factor.

In recent years, economic volatility and governmental/policing policies have been met with a rise in cargo thefts and truck robberies.

Also consider that your talent stream can be threatened by factors such as rising housing costs, which can lead to slow onboarding and knowledge loss.

#8 Made in the USA

Sourcing your chemicals from inside the United States can do more than just earn you goodwill.

You’ll also get the benefits of high quality, access to low-cost natural gas, an educated workforce, protection for intellectual property, and strong regulatory controls, each of which could save you money in their own way.

#9 Domestic vs. International

On a strictly cost-basis, offshoring your chemical manufacturing typically trumps domestic production, as you can opt for the cheapest rates available in the world.

But even in offshoring, cheapest isn’t always best as language barriers, political upheaval, and other disruptions can create unforeseen expenses that eat into your savings.

#10 Availability of Skilled Labor

When it comes to workforce education levels, if you want the best of the best, you’ll need a facility located reasonably close to a big city.

The so-called “production amenity” of enhanced productivity in urban centers is a result of college-educated adults choosing to live in areas with higher-end housing, lots of amenities and cultural attractions, and high wages.

Seatex Is a Strategically Located Chemical Manufacturer

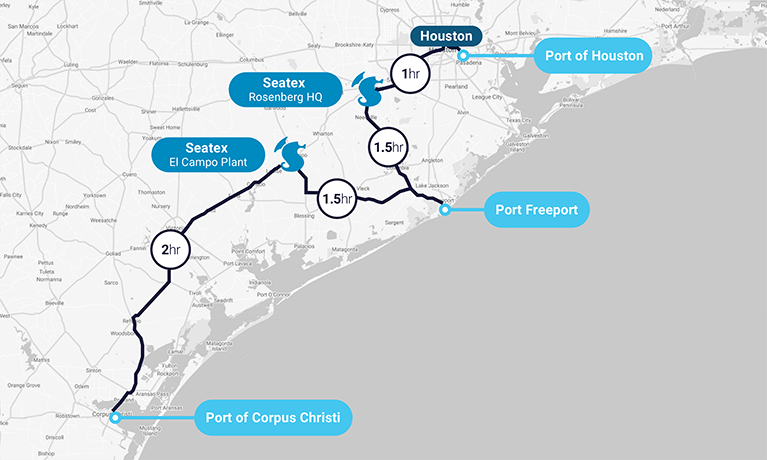

Seatex is headquartered in Houston, Texas, a major American city and hub of chemical production in the U.S.

With one of the world’s largest ports and the benefit of being in a state with by far the most miles of freight railroad, Houston also boasts a strong labor force and steady supply of engineers from area colleges and universities, which are some of the top in the nation.

Seatex’s own facilities are perfectly positioned to take advantage of these benefits, with both of our locations lying within two hours of port access and immediate access to railroad lines.

By continuing to deliver orders through pandemics, extreme weather events, economic downturns, and more, Seatex has proven we are the perfect chemical partner for your business.