Specialty Chemicals Manufacturer for Complex Formulations

Seatex boasts the physical assets and mechanical capabilities to handle the toughest R&D and manufacturing challenges industrial companies face.

Combine them with our good manufacturing practices certification and HSE policies, and our integration with packaging services, and you have a truly one-stop-shop at your disposal.

Seatex is able to deliver industrial chemicals of any complexity, ranging from simple compounds (e.g. free-flowing, non-foaming) to dangerous formulations, such as flammable or toxic materials. We pride ourselves on our custom services that may demand non-standard equipment or unique capabilities.

We perform custom chemical blending that meets any and all specialty chemical requirements, including:

- Custom particle sizes to as small as 10 microns

- Distribution through advanced milling techniques

- Solid/liquid incorporations

- Complete molecular change

Whether your specialty product requires liquid blending, dry blending, grinding and milling, or a customized process, Seatex offers a wide range of chemical manufacturing services backed by over 50 years of experience.

How Seatex Meets Your Specialty Chemical Needs

Serving Multiple Markets

Coatings, Adhesives, Sealants, and Elastomers

CASE chemicals touch a huge range of industries, and Seatex is equipped to manufacture them all.

- Corrosion inhibitors

- Flame retardants

- Concrete sealants

- Epoxy resins

- Latex blending

Household, Industrial, and Institutional Cleaning

Seatex Jan/San (janitorial/sanitation) supplies deliver premier dirt- and germ-fighting power.

- Degreasers

- Odor counteractants

- EPA sanitizers and disinfectants

- Detergents

Lubricants and Metalworking

Use Seatex fluids to improve operations in your machining, grinding, metal cleaning, and many other industrial applications.

- Solvent blending

- Base oil blending

- Moisture scavengers

- Emulsifier and surfactant formulations

- Rheology modifiers

We Handle Even the Toughest Custom Chemical Requirements

Heated Products

For any performance product that requires the addition of heat to achieve your goal, our facilities can accommodate atmospheric reactions up to 400 degrees. In our jacketed tanks and heated shakers, we can use any combination of heating and cooling to reach the right temperature profile for your blended or reacted products.

Flammable Materials

Whether you need to lower a formulation’s freezing point without watering it down, or you need a solvent to allow for pumping a product, a flammable additive such as ethanol is often the best option. With our brand new flammable blending facility, our ability to safely and cost-effectively handle BTEX (benzene, toluene, ethylbenzene, xylene) and other hazardous materials is second to none.

Molecular Change Reactions

As a one-stop-shop chemical manufacturer, we handle true specialty chemistry just as readily as simple mixing. When your formulation’s specs call for complex science, we have the tools and the expertise to produce singular compounds while managing their unique reactions and necessary environments.

Scrubbing and Gas-off

Government bodies and consumers alike demand chemical products that are environmentally friendly, both in their production and their application. In our processes, we effectively scrub VOCs and other unwanted byproducts through negative pressure space inside our tanks. We commonly neutralize ammonia, although we are able to scrub many different types of harmful or unwanted gases that may be generated during molecular changes.

Specialty Equipment for Specialty Chemical Manufacturing

We can deliver and perform molecular change reactions, solid-liquid incorporations, flammables, specialty products like ammonia derivatives, and more thanks to our cutting-edge specialty equipment.

Seatex Specialty Chemicals in Action

These are just a few examples of ways that Seatex has met the unique needs of our customers:

Stateside Service for a Foreign-based Vendor

On multiple occasions, international companies have engaged Seatex to be their domestic manufacturer of specialty chemicals:

- For a phenolic-formaldehyde resin company, Seatex served as a secondary supplier, producing a chemical intermediate using raw materials sourced overseas.

- In another case, we provided the domestic manufacturing footprint for a transition metal catalyst regeneration company.

- Finally, we performed supplementary blending and reacting of amine-based chemistries used in the refining industry.

Serving a Secondary Manufacturer

A long standing customer was looking to diversify their supply chain for a large-volume reactionary product, one that required advanced technical capability.

Once the chemistry had been jointly reviewed and capital approved, we secured the necessary equipment and scaled to production batches in less than three months.

Get in Touch with Our Industry Experts

John Fries Sr.

Agriculture and Specialty ChemicalJohn Fries Sr.

Agriculture and Specialty Chemical

Core Services

Reactions

Seatex can handle your atmospheric reactions including Endothermic, Exothermic, Ammonization, Condensation, and many others.

find out more

Custom Manufacturing

Seatex’s custom formulation and manufacturing processes utilize a diverse set of equipment, configured in such a way that we can customize a manufacturing process to fit your requirements.

find out more

Liquid Blending

From Hazardous to Non-Haz, from simple to highly complex, Seatex has the capability to handle more than 100,000 gallons a day of custom blends, dispersions, suspensions, and packaging.

find out more

Dry Blending

With rigid standards and unmatched flexibility, Seatex offers precise dry blends with package sizes from pouches to bulk rail.

find out moreTurnkey Chemical Services

We bring our expertise to bear at every stage of your molecule’s life, simplifying your supply chain and giving you one point of contact. Everything we touch is backed by our dedication to our customers and our commitment to operating with integrity at all times.

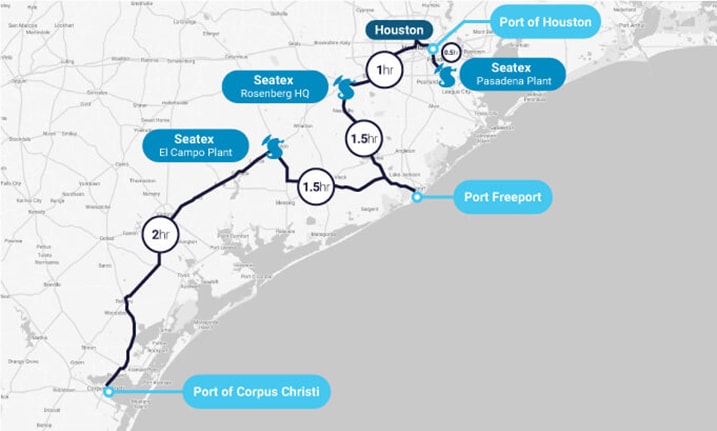

Serving You at Multiple Strategic Locations

We’re proud to offer our customers service at multiple locations in South Texas, each with convenient access to both rail and shipping lines. We save companies significant costs by performing blending, packaging, and labeling all in-house, rather than paying to have these services done by third parties across the country.

Seatex Location AdvantagesAccredited to ISO 9001:2015 and facilities certified to EPA, GMP, NSF, Kosher, and UL standards.

See all locationsPackage, Label, Store, and Ship Any Way You Need

Whether you need us to warehouse your chemicals or get them where they need to be quickly, Seatex comes through. Our Rosenberg facility is served by on-site, on-demand railcar service, and our Rosenberg, Pasadena, and El Campo locations are within easy reach of the Port of Houston.

Looking for a hard to find package size? Seatex stocks a full spectrum of options that can be labeled here in-house with your design or ours.

Tanker Truck

Railcar

Tote

Drum

Pail

Gallon

Quart

Jar

Boxes

Bulk Sacks

Bottle

Bag

Zip Lock Bag

Pouch

Zip Lock Pouch

Rigorous QA and QC Protocols at Every Stage

Seatex’s Quality Assurance and Quality Control protocols ensure accuracy and reproducibility in your products, help you meet or exceed regulatory standards, and protect your brand. We are ISO 911:2015 and GMP certified with a full-time Quality Specialist on staff.

For us, QA and QC are the nuts and bolts of how we deliver excellent products, each and every time, just as we promised, with the data and reports to back it up.

Certifications

Our Custom Packaging Capabilities from 1 Gallon to Rail Car

Seatex is a specialty chemical technology manufacturing solutions company based in Rosenberg, TX.

445 Highway 36 N Rosenberg, TX 77471

© 2024 Seatex LLC. Privacy Policy