5 Ways Seatex Helps Make Your Business More Recession-Resilient

- September 12, 2022

- Blog

All the signals are flashing–an inversion of the U.S. Treasuries curve, consecutive months of falling GDP, rising interest rates to combat inflation–that recession is imminent, if not already here.

Prudent business owners are looking down the road at what’s likely coming their way and making moves now to get ready for a period of lower sales, tighter capital, and supply chain uncertainty.

Now more than ever, a reliable manufacturing partner can be a bridge over troubled economic waters.

Below you’ll find five ways Seatex can be the one-stop shop that helps you withstand a recession’s effects.

The Chemical Industry: A Pillar of the U.S. Economy

For a company like ours to be able to help you through a recession, it has to be able to thrive through a downturn itself. Fortunately, the chemicals sector is one of the main supports of economic activity in America–25% of total U.S. GDP by the numbers–with a direct impact on thousands of products used and sold around the world. In fact, it’s not a stretch to say chemicals shape life as we know it in the 21st century.

Here at Seatex, we’ve weathered no fewer than seven recessions since our founding in 1967, most recently in 2020. For a time, we pivoted to producing vast amounts of hand sanitizer, both as an economic decision and to help keep our community supplied with germ-fighting products during the COVID-19 pandemic.

In short, if your product or process involves chemicals, you can count on our doors remaining open through thick and thin.

How Seatex Helps Recession-Proof Your Business

1. Avoid Major Infrastructure Investments

Just before a recession hits would be one of the worst times to finance a large equipment or machinery purchase. Getting that debt off the books could prove extremely difficult if cash flows dry up. And that’s on top of the potential headaches that a looming recession could cause for actually securing the equipment, e.g. inflated prices, out-of-stock products, etc.

An established contract chemical manufacturer already has all the necessary tanks, blenders, mills, and other infrastructure in place ready to be put to work.

Seatex Equipment at a Glance

- Liquid Vessels (100 gal.-16,000 gal.)

- 10,000 gal. Stainless Steel Vessels

- 7,500 gal. Stainless Steel, Low Flashpoint Vessels

- 6,000 gal. Poly Tanks

- Ribbon Blender

- Paddle Blender

- Littleford Mixer

- Bulk (tanker trucks and railcars), intermediate (totes and drums), and small (5 gal. > 32 oz jugs) packaging options – 10 packaging lines

2. Keep Your Customers Happy

There’s nothing like a recession to make shoppers question their loyalties, as they tighten their belts and look for ways to save. Whether your business is B2B or B2C, you can’t risk displeasing your customers at a time like this, whether through late shipments, subpar quality, or even just poor communication.

And though the number varies, marketing experts say it costs anywhere from five to 25 times more to attract a new customer than to retain one, and a recession would likely push that cost to the higher end.

At Seatex, the quality of work we do translates directly into keeping your customers happy.

Our thorough QA/QC, specialty chemical capabilities, and custom packaging can all play a role in ensuring you and your product are indispensable to your audience. And when it makes sense for your business, we can support you with direct sales and customer service training, using our knowledge of your products to help you optimize the experience for the end user.

3. Develop a New Revenue Stream

Our expert R&D department can also be a key to recession-proofing your business, by helping you develop a new chemical product that you can bring to market and potentially tap into a whole new source of revenue.

Maybe this could be a greener version of something you already make, a tweak of an existing product, or an innovative new compound that poses a more budget-friendly option for consumers than available alternatives.

By diversifying your revenue streams, all your eggs won’t be in one basket and at risk of being crushed by recessionary factors.

4. Bank on a Stable Supply Chain

As we’ve alluded to, supply chains often become roiled during times of uncertainty such as a recession, or the run-up to one.

The reality is that uncertainty has plagued the market since roughly April of 2020, when COVID-19 first began to really impact the global economy, and supply chains for many sectors have not fully recovered as of Summer 2022.

A full-blown recession could very well re-create some of the supply chain pain many businesses felt in trying to secure raw materials during the “pandemic” era.

Source diversification is the key to riding out supply chain storms, and we have relationships with vendors from a wide variety of areas, both local and international. If one gets hamstrung by a worker shortage, we can switch to another. What that means for our customers is their orders will be delivered on time, so that you can meet your obligations and keep your income stream flowing.

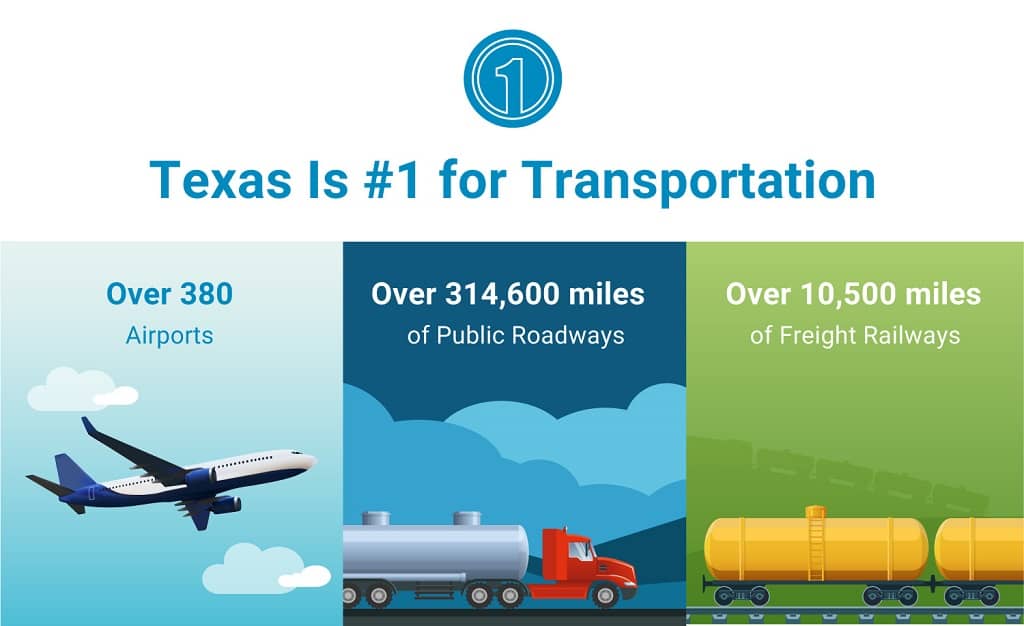

5. Keep Transportation (and Other) Costs Down

A penny saved is a penny earned, and where your contract manufacturer is located can save you serious money.

In our case, we’re able to offer customers a variety of shipping options so that they can choose the most appropriate and cost-effective method or a combination of multiple methods.

This includes fuel-efficient rail (we have rail spurs at both locations), ship (we have three ports within two hours of us), truck (our home state has the most public roadways in the country), and plane (we have two major airports less than 90 minutes away).

Seatex Can Help Shore Up Your Bottom Line

As a one-stop shop for all your chemical manufacturing needs, we ‘cut out the middleman’ and help lower your costs when it matters most.

We offer grinding and milling, dry and liquid blending, synthesis reactions, packaging, logistics, and more, with a wealth of major industry certifications behind us.